Scope 3.1: Production goods & materials

Raw materials, partially and fully formed parts or components that are purchased by the company for use in manufacturing of goods.

Production goods & materials are raw materials, partially and fully formed parts or components that are purchased by the company for use in the manufacturing of goods. This category covers the upstream (i.e., cradle-to-gate) emissions for materials and products purchased or acquired by the company as part of their supply chain, e.g. raw materials and products for resale.

In this case, cradle-to-gate includes:

-

Emission from material sourcing, extraction, and transportation to the point of leaving the tier 1 (direct) supplier. Meaning, these emissions occur before the goods are transported to the purchasing company. The exact life cycle boundaries may vary depending on the emission factor selected.

In this case cradle-to-gate excludes:

-

Emissions from the transportation of purchased products from a tier 1 supplier to the reporting company, as these are accounted for in the Cozero category “Purchased logistics”.

Production goods & materials can have different manufacturing methods with varying emissions impacts

| Production good/material | Description |

| Primary materials purchased |

Extraction and acquisition of raw materials (e.g. metals and coal which are mined, oil drilled from the ground, rubber tapped from trees), or purchase of raw materials that are then used to produce goods by the reporting company. Cozero also allows for a separation of supplier energy and material inputs of purchased production goods to facilitate the hybrid method. For more details on this, please refer to Section 3 on How to use the subcategory: Purchased goods - Supplier production data. |

| Re-used | Material is re-used or re-purposed in the manufacturing process. |

| Closed-loop recycling | A product is used, discarded, captured, and then the component materials are recycled into a new product of similar functionality. It is then itself used, discarded and captured, to be recycled again, continuously cycling the material resource through the supply chain for the same product. |

| Open-loop recycling | In this case the material is recycled in an open-loop process. This means that the output product is not the same as the input recycled material (e.g. plastic PET bottles being recycled into material for clothing). As a result, the material is made into a substantially different product with different properties. The output product is often non-recyclable or has degraded recycling capabilities. |

1) How this category aligns with carbon accounting standards

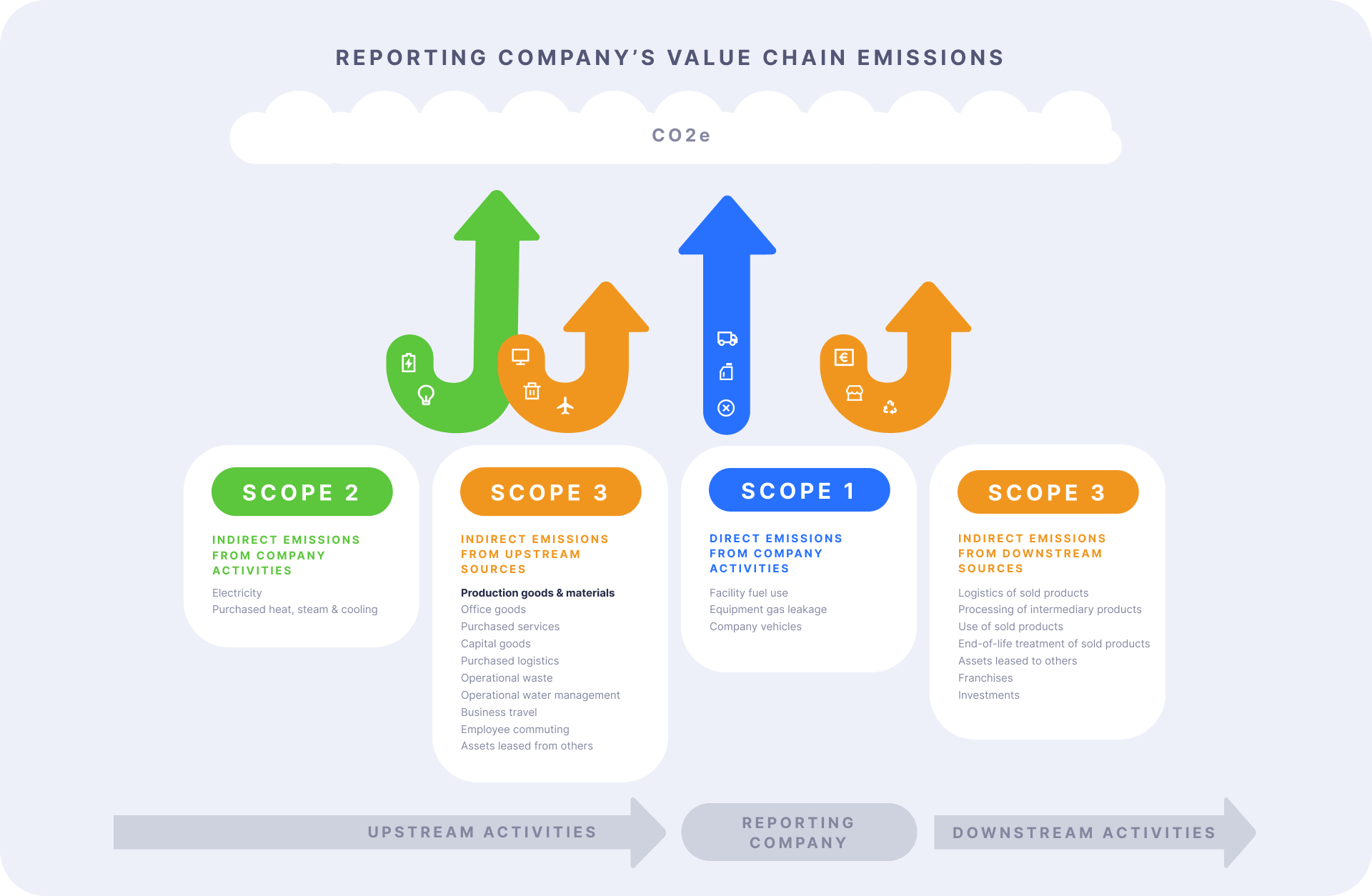

The Cozero category, Production goods & materials is a source of upstream Scope 3 emissions, as defined by the GHG Protocol. All Cozero emissions calculation methodologies follow the requirements for this Scope of emissions accounting.

The GHG Protocol Corporate Standard

The GHG Protocol Corporate Standard is an internationally-recognized go-to standard for estimating and reporting corporate GHG emissions. GHG emissions are categorized into three ‘Scopes'. For further information see here.

Scope 1 includes direct GHG emissions that originate from sources that are owned or controlled by the reporting company, e.g. generation of electricity, heat and steam, physical or chemical processing, transportation of materials and fugitive emissions. They are the most important source of emissions because they are the direct result of companies’ activities.

Scope 2 encompasses indirect emissions from the generation of purchased or acquired electricity consumed by the reporting company. These emissions are considered to be indirect because they arise as a result of the reporting company’s activities, but they originate from sources that are owned and controlled by external entities.

In turn, these emissions are categorized as Scope 1 for the energy generator that produced the electricity, given that they arise from their owned and controlled resources.

Scope 3 emissions are all indirect emissions (not included in Scope 2) which occur in the value chain of the reporting company. In other words, the emissions that are linked to the company’s operations but are outside of its control. Scope 3 emissions can be categorized into two high-level groups:

-

Upstream emissions: Indirect emissions related to the procurement of goods and services, starting from the initial sourcing and pre-processing stages. Upstream emissions can be attributed to the materials’ extraction, production and transportation processes before they reach the company.

-

Downstream emissions: Indirect emissions related to products and services sold by the reporting company, occurring after the products have been sold to the customer or end-user. Downstream emissions relate to activities such as distribution, storage, usage by consumers, and the eventual end-of-life disposal or recycling of the products.

2) Calculation methods

Here are the various calculation methods available in Cozero for calculating Scope 3 emissions from Production goods & materials. Users should choose the method that is the most appropriate to the data available to them, to their business goals and the significance of the emissions of the category.

2a. Quantity of goods method

Emissions are calculated by collecting data on the quantity of materials bought during the reporting period and multiplying by the relevant emission factor.

• Activity data: quantity of material bought within the reporting period in kg. Cozero provides conversion of other units of mass.

• Emission factor: Cozero provides a default emission factor of the production materials per mass of product but users can also enter custom or supplier-specific emission factors.

How to report emissions in Cozero?

• Step 1: Select the category “Production goods & materials”

• Step 2: Select the subcategory (production good) you want to report on

• Step 3: Select “Quantity of goods” as calculation method

• Step 4: Select the activity data source

• Step 5: Enter the amount of materials consumed

• Step 6: Select the appropriate data quality and where the data was procured from

Cozero will automatically calculate the emissions for the amount of material entered.

2b. Spend method

Emissions are estimated by collecting data on the economic value of production goods and multiplying by the relevant emission factor.

• Activity data: amount spent on production goods within the reporting period. The user can select one of the available currencies from the dropdown.

• Emission factor: Cozero provides a default emission factor of the production good per unit of economic value. Entered currencies are converted as needed automatically to match the emission factor.

How to report emissions in Cozero?

• Step 1: Select the category “Production goods & materials”

• Step 2: Select the subcategory (production good) you want to report on

• Step 3: Select “Spend” as calculation method

• Step 4: Select the activity data source

• Step 5: Enter the amount spent on the production good

• Step 6: Select the appropriate data quality and where the data was procured from

Cozero will automatically calculate the emissions for the spend entered.

2c. Direct CO2e entry

Users can enter the amount of emissions in CO2 directly in the Log. Make sure of the accuracy of data used in this estimation.

3) How to use the subcategory: Purchased goods - Supplier production data

Cozero’s subcategory Purchased goods - Supplier production data can be used to track Scope 1 and 2 emissions of suppliers. It captures the emissions of suppliers’ energy consumption and process emissions for manufacturing the production goods that are purchased by the reporting company. By this separation into a distinct subcategory, it also enables companies to use the hybrid method defined by the Greenhouse Gas Protocol’s Scope 3 Standard to account for their emissions from purchased production goods & materials.

What is the hybrid method?

The hybrid method is a GHG Protocol–recognized accounting approach that combines supplier-specific activity data (when available) with secondary data to fill any gaps. This method can be utilized if a supplier cannot provide product-level data on some of the products’ emission sources, therefore preventing a conventional PCF calculation. The reporting company may in these cases combine the supplier-specific data with secondary data.

To account for upstream emissions of production goods and materials, the reporting company should collect as much activity data as possible including suppliers’ allocated Scope 1 and 2 inputs or emissions (e.g. electricity and fuel use) and the mass or volume of material inputs.

The hybrid method in 3.1 Production goods & materials

Cozero’s subcategory Purchased goods - Supplier production data supports a streamlined approach by separating material-related emissions from energy-related emissions. This allows companies to:

- Use supplier-specific activity data on energy or process emissions inputs (for example by allocating the supplier's total energy-related consumption proportionally based on the company’s share of the supplier’s revenue or products’ energy consumption of total consumption). Companies can then apply standard emission factors from Cozero’s database to these inputs.

- Use supplier-specific activity data (e.g., the weight of raw materials purchased) to account for emissions from materials together with secondary data emission factors from Cozero’s database.

By combining supplier-specific h energy data and materials quantities with secondary data emission factors, companies can still account for the full lifecycle emissions of purchased products - even when suppliers cannot provide product-level emission breakdowns.

4) Where can I find the relevant data?

-> Internal data systems (e.g. bill of materials)

-> Purchasing records

To find out more about data collection, you can refer to the article about Data Sourcing.